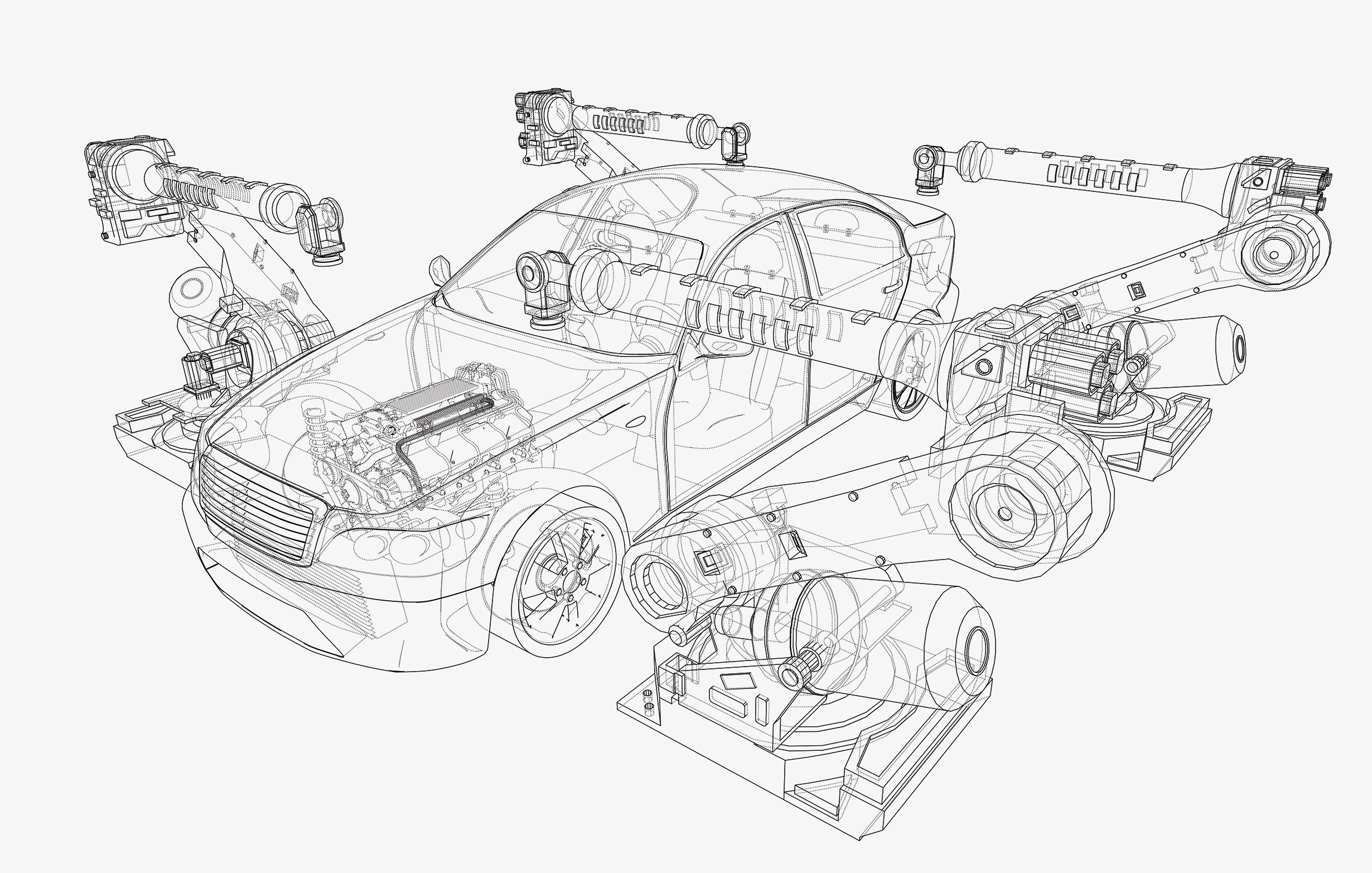

Stop Solving Problems

— Start Preventing Them

Owner & President, Michael A. Anleitner, is widely recognized for his expertise in product development systems & methods, including Failure Modes & Effects Analysis, Design Verification & Production Validation.

He has over 50 years of industrial experience, and holds a B.A. degree in technical communications from Michigan Tech, a B.S. degree in engineering from Wayne State University in Detroit, and an MBA from the Ross School of Business at the University of Michigan.

Michael founded LTS in 1985 to provide training and consulting services to companies that manufacture products, and more.

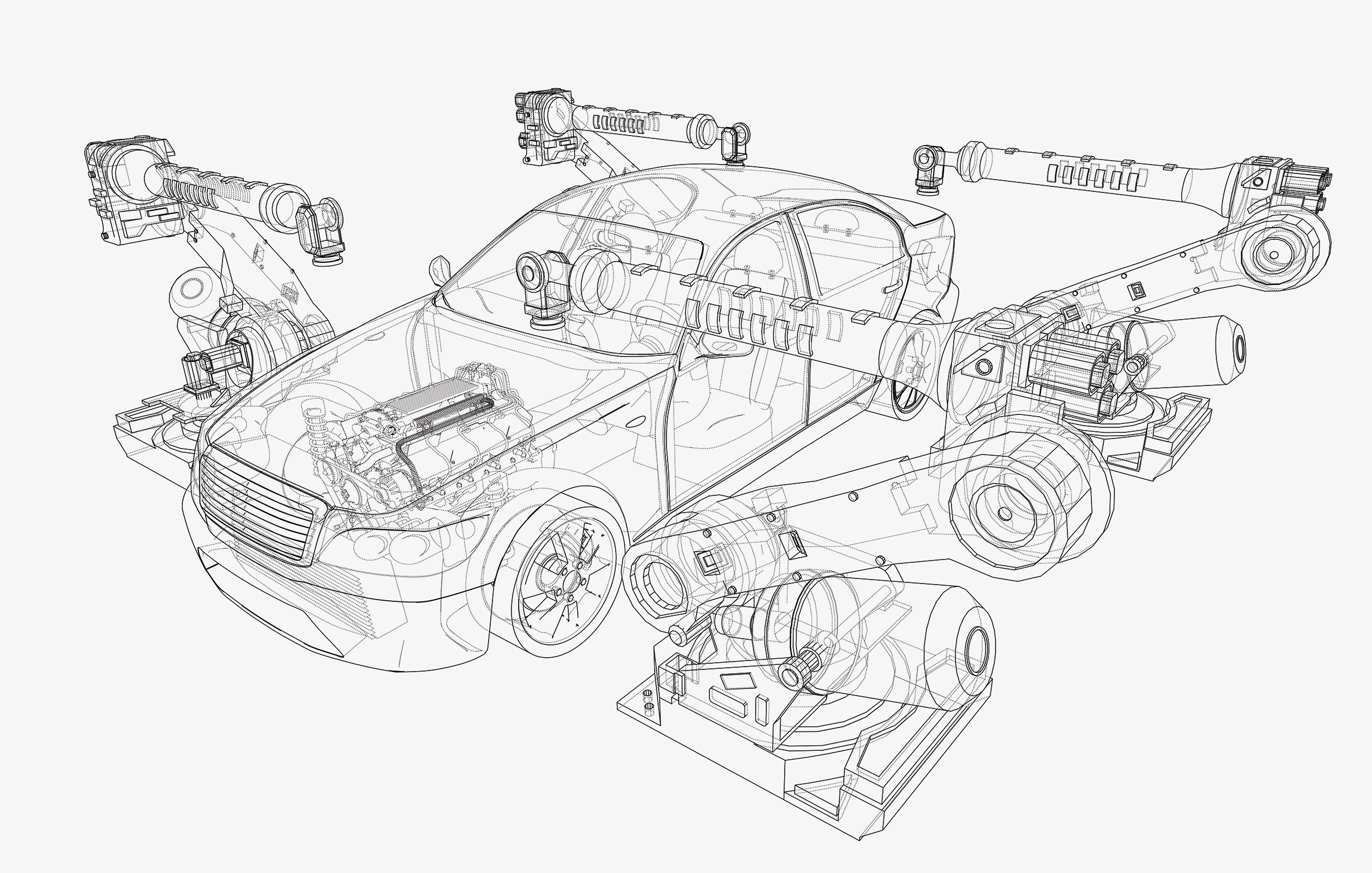

Stop Solving Problems

— Start Preventing Them

Owner & President, Michael A. Anleitner, is widely recognized for his expertise in product development systems & methods, including Failure Modes & Effects Analysis, Design Verification & Production Validation.

He has over 50 years of industrial experience, and holds a B.A. degree in technical communications from Michigan Tech, a B.S. degree in engineering from Wayne State University in Detroit, and an MBA from the Ross School of Business at the University of Michigan.

Michael founded LTS in 1985 to provide training and consulting services to companies that manufacture products, and more.

These 4 Management Activities Drive Success

We believe these areas greatly impact the success of manufacturing operations across the globe.

These 4 Management Activities Drive Success

We believe these areas greatly impact the success of manufacturing operations across the globe.