There’s an interesting article published by Machine Design written by Dr. David Ullman comparing “scrum” methods with stage-gate (or “waterfall”) processes.

Ullman, who is a well-known expert in product development methods, presented data suggesting that scrum methods cut project failure rates in half. Good result, but unless you read carefully, you may not have noticed that this was for software and did not relate to hardware.

As Ullman noted, software is less vulnerable to factors that make hardware development difficult. This relates to tooling and production investments—which are minimal or absent in software projects—but also includes greater difficulties that hardware faces in analysis and testing.

Nevertheless, as I’ve found in 47 years of experience with product development processes, hardware-driven projects can have high success rates using stage-gate processes. I’ve personally participated in re-structuring these processes for a number of firms, and, when the process is properly constructed, the failure rate for projects is usually less than 10%.

What’s the Major Factor in Failure?

One of the challenges in hardware design, whether you use scrum or stage-gate, is starting the project properly. If you don’t start well, the chances for failure rise dramatically.

Unfortunately, too many managers, who learned their craft with methods in use 10-20 years ago, have a strong preference to see hardware in some form as early as possible in the project timeline.

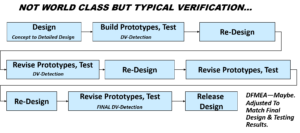

That’s a major problem. It’s all about how you get to verification of the design. In a hardware-first culture, here’s what I have seen time and time again:

Once a basic concept design is generated, there’s a rush to get prototypes that can be looked at, touched, and most importantly, tested. Of course, these early prototypes don’t work properly, so the design is reworked. More samples are tested. They do better, but still don’t meet the goals. This is repeated again and again, usually until time runs out and the design is pushed over to the manufacturing team.

Results of Hardware-First Methods

The net result is the design team learns what doesn’t work, but often doesn’t understand why the design works (assuming final test results actually meet project goals). It’s also next to impossible to control project timing with this method.

The goal becomes simple: build prototypes that will pass all of the required tests.

And, finally, the manufacturing side of the team is slowly losing their minds as engineering changes keep coming until the product is launched. If you’re lucky, changes slow down, but usually keep trickling in for a year or so.

When the product reaches customers, there are often problems. It could be that the tests used didn’t reproduce real-world conditions very well. Often, customers use products in ways the design team didn’t anticipate.

Manufacturing costs and capital budgets are battered and market acceptance can be irreparably damaged.

What You Should Aim For

To avoid this pitfall, managers and executives need to be more patient and deliberate in the early stages. That doesn’t mean using time in a leisurely fashion—far from it. Instead, project teams need to move at breakneck speed, but be more structured and focused.

Instead of a goal that designs need to pass necessary tests, the project goal must be broader. This reflects what Dr. Joseph Juran defined as “quality.” The goal must be to arrive at a properly verified design that is fit for use by targeted customers.

Test criteria can never fully6 address that. There are dozens of reasons why, but I’ve studied this at length, and I find almost no products that failed in the market that didn’t pass tests used to verify the design.

How to Do Better

To create a product that is “fit for use,” spend some detailed, intense time trying to determine all of the functional requirements that will satisfy your customer base.

There’s a lot to do to achieve that, but it can be achieved quickly and comprehensively by following a simple outline.

As with the “early hardware” method, start with a concept design. That means a design that is far enough along to create a rough costed bill of materials.

Then follow these five steps:

-

- Create a block diagram for the entire product.

- Decide which sections of the block diagram—what Ullman called modules—cause concern. This will usually be subsystems or components that are new, unique (in terms of application), or difficult. These design elements are sometimes called “NUD’s.”

- Next, create a Parameter diagram, and try to determine what the modules of interest must do to make the system work correctly. If you are supplying something that will be used in a bigger system, this will include your customer’s system. You’ll also need to identify the environmental conditions that the product must withstand, as well as the important user factors that will make your product robust against reasonable and expected misuse.

- Use the block diagram and the Parameter diagram to create an interface matrix. The resulting functions that fill the matrix will be a detailed requirements statement that need to be evaluated to achieve verification.

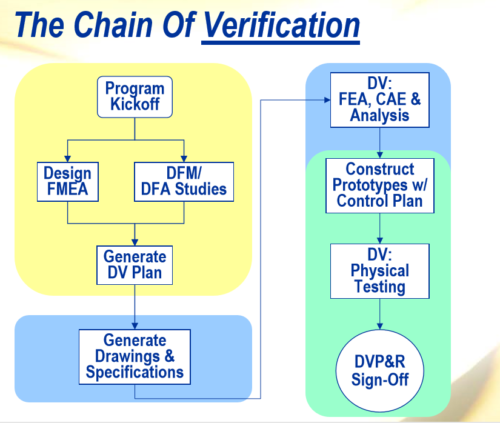

- Use that list of functions to generate a Design Failure Modes & Effects Analysis. The resulting analytical prevention controls and physical detection controls will give you a list of things needed to achieve verification.

Carry out the analytical prevention controls before you build any significant test samples. Use analytical techniques to debug and modify the design.

Now, build prototypes and conduct the detection-driven control tests.

If you’ve done this well, the odds are you won’t be endlessly repeating tests with multiple hardware iterations. You’ll be able to stay on schedule, be on budget, and have a design that the manufacturing team won’t have to continuously change as they complete their preparation for production.

The Outcome

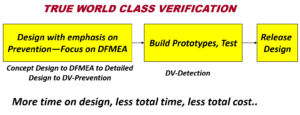

If you’ve done the proper analysis outlined above, your process outline will now look like this:

Of course, there are a lot of details in this process, but the improvement in project cost, project timing, and launch issues is the payoff you can expect from this process. And it fits very well in the familiar outline of a stage-gate process.